We’re thrilled to welcome you to our facilities for an immersive learning experience focused on the versatility, quality, and beauty of Western red cedar. Get ready to dive into a world of cedar knowledge, innovation, and craftsmanship as we explore the endless possibilities of this remarkable wood species.

Cedar School

- Notable differences

- Drying requirements

- Grade specifications

- Size specifications

- Manufacturing

- Surface finishes

- Rot resistance

- Distinct colours

- Highly stable

- Takes stain

- Colour

- Stability of green vs. when kiln dried

- Rot resistance

- Ability to take stain colors

- Unique colouring

- Strength MOE: 30% higher WRC | 20% Less than DFIR

- Rot resistance

- Excellent deck product

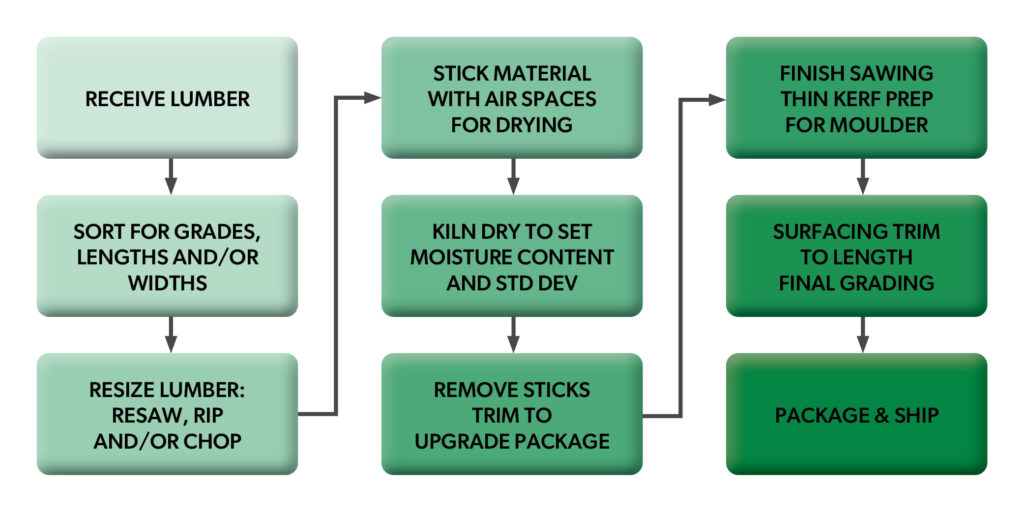

Wood Drying Methods:

- Air drying

- Conventional kilns

- Vacuums kilns

- Radio frequency vacuum kilns

- Steam kilns

- You can destroy or properly dry any product in each method

- Drying too fast can damage

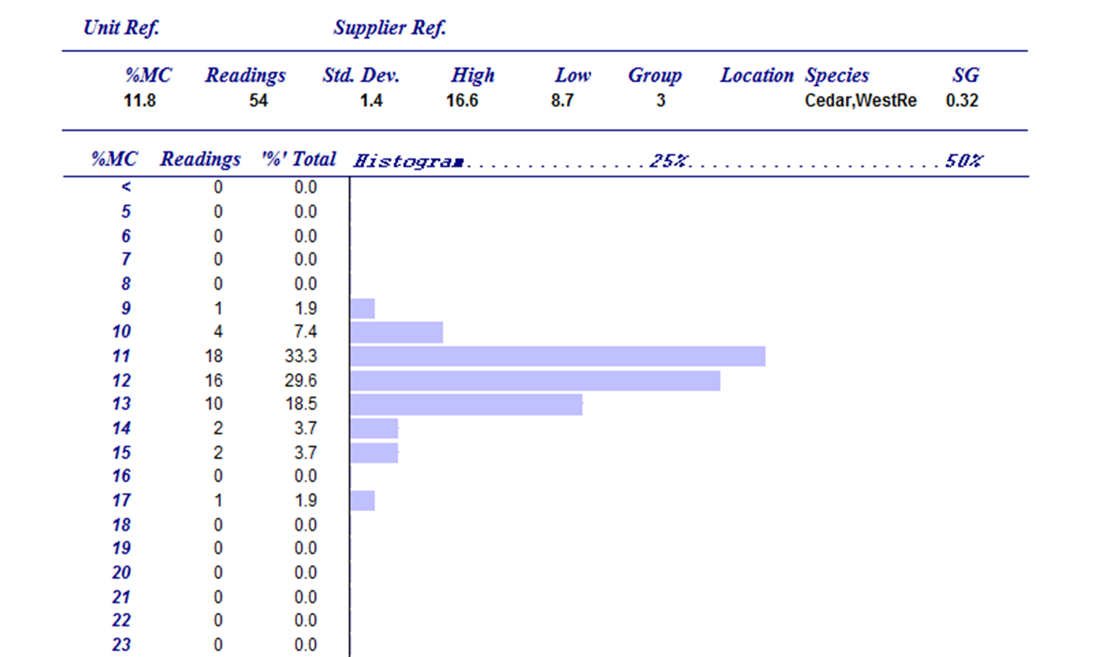

- Drying to statistically tested moisture ranges is the most important quality control metric. The average and standard deviation combine to tell you how much of the wood is dried to an acceptable moisture content

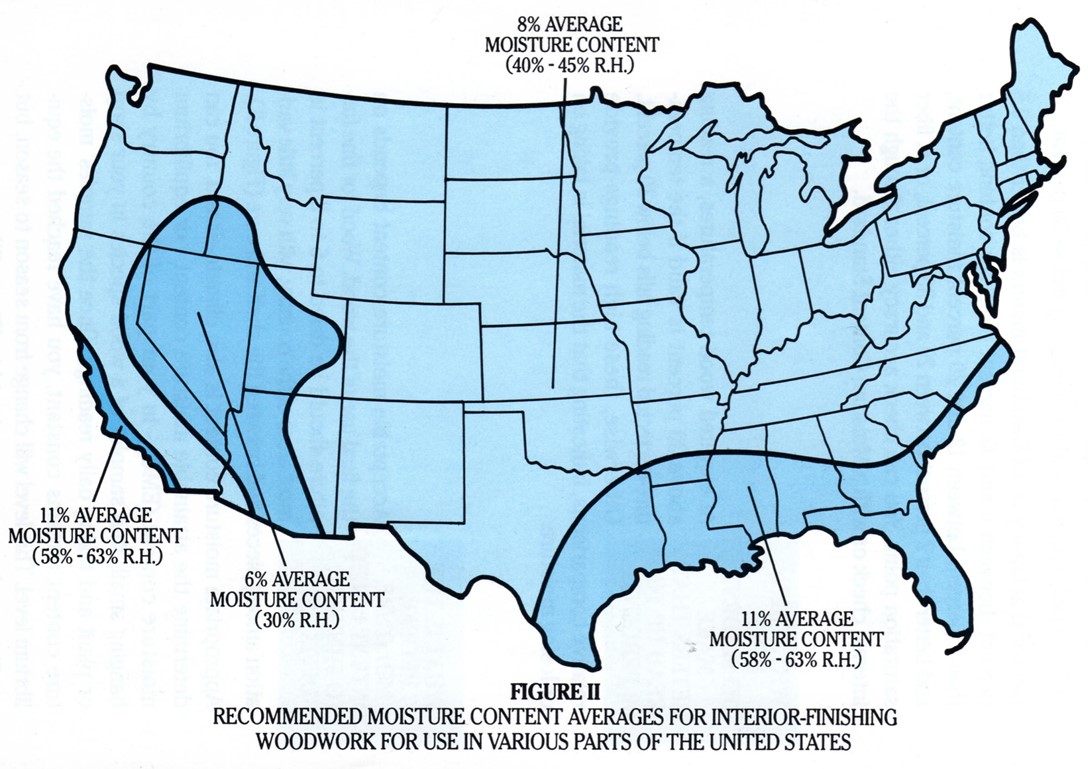

How dry is dry enough?

- Phoenix 6-10%

- Napa Valley 9-13%

- Miami 11-15%

- Alaska 13-17%

Wood will try to achieve equilibrium with its climate.

The range is more important than the average – ie: if you are in Phoenix with an average of 8%, it should be good, but if the standard deviation is 3%, you will have many pieces over 10% and those pieces will continue drying to achieve equilibrium – resulting in shrinking and warping.

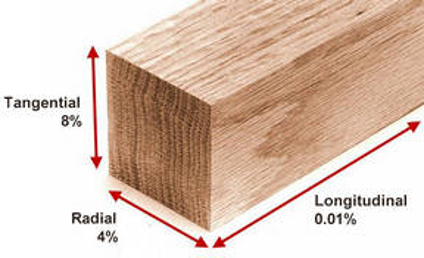

- Wood continues to shrink by ½ – 1% per 4 percentage points MC under the Fibre saturation point (~ 28%).

- Wood gets noticeably more brittle as it dries further. Harder to machine and install without checking, chipping and breaking.

Do you want knots?

What is your tolerance for natural defects?

Does grain orientation matter to your application?

- Rougherheaded grade

- Usually sold green

- Okay for outdoor uses

- Not recommended in yellow cedar – too much warping as it dries

#2 & Better Appearance for Timber applications

- Can be kiln dried for added value

- Green red cedar – okay

- Select structural if there is an engineering requirement

Select Tight Knot (STK) – Siding/Trim/Decking

- 1” & 2” finish product

- Kiln dried only

- Not air dried

- Exception some decks

- No heart spec needed

Default to A & Better Clear (allowing 15% B)

- 1” & 2” finish product

- Kiln dried only

- Allows some knots and small defects

- Interchangeable with #2 Clear Spec – which is more common for 3” & thicker specifications

Other Clear Grades

For these, ask for a copy of the grade rule and compare to A & BTR.

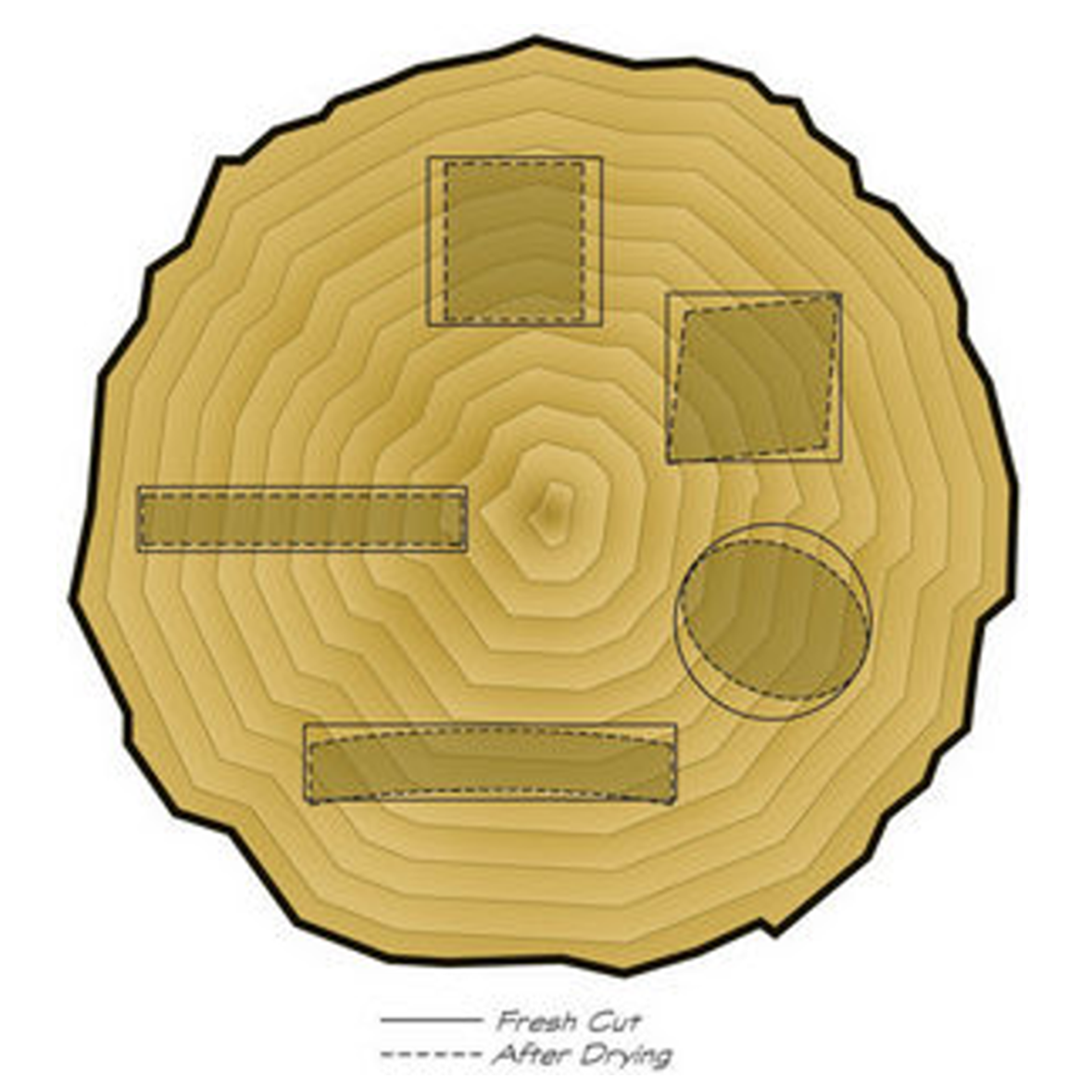

Vertical vs Flat vs Mixed Grain

- Default is mixed grain

- All knotty is flat grain, only specify flat grain when specific look is needed in clear

- Vertical grain A & BTR will have less defect than mixed grain due to the way knots form

- Vertical grain is more stable than flat grain

Nominal Finished Sizes

1” > 11/16”

5/4” > 1”

2” > 1.5”

4” > 3.5”

6” > 5.5”

8” > 7.25”

10” > 9.25”

12” > 11.25”

- Mill Rough Green

- Lowest cost option

- Full Size available

- Will shrink / warp / check

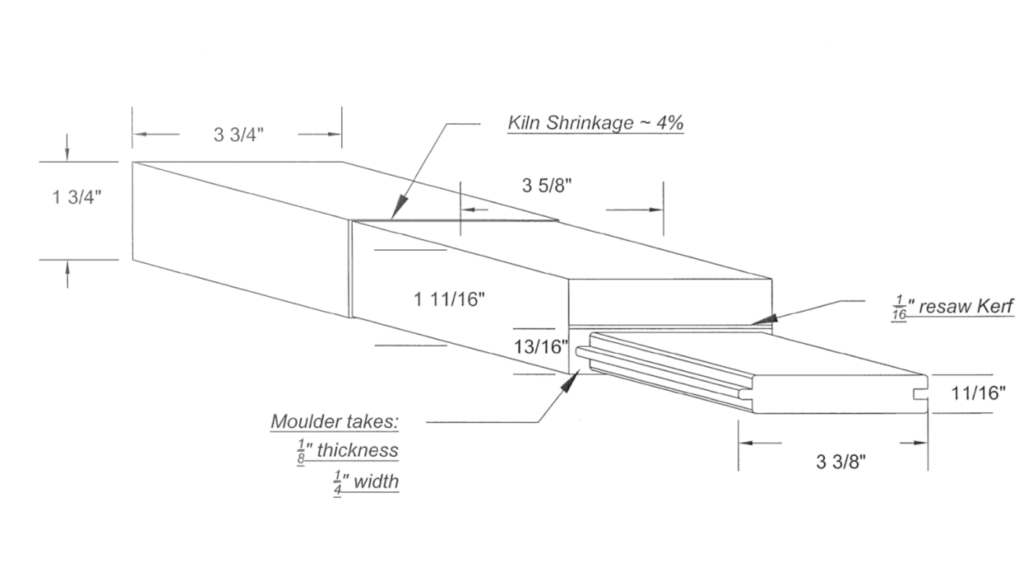

- Resawn After Drying

- More uniform finish with fine tooth saw

- Standard sizes required (Shrinkage, Saw Kerf)

- After drying = no shrink / warp / check

- Smooth face and edges

- Specify eased or square edges

- Square edges are brittle and don’t take stain well

- Sanding option

- WRC – for high end finish

- YC – needs to be sanded for staining

- Rougher headed

- Comb face

- Wire brushed

- Custom runs

Thank you for attending 2024 Cedar School.

We’d love to hear from you. If you have any questions after the WRCLA 2024 Cedar School hosted at PowerWood, please let us know and we will do our best to answer.